Software development

AMIDR: A Complete Pulse Method for Measuring Cathode Solid-State Diffusivity

The Atlung Method for Intercalant Diffusion and Resistance (AMIDR) is a novel, high accuracy method for measuring solid state diffusivity and interface resistance related to the Atlung Method for Intercalant Diffusion (AMID) with several key differences. Most notably, AMIDR is designed to analyze the voltage response over time of “complete” pulses, pulses that last until an impedance steady state is reached. These differences, in addition to design considerations made when designing AMID, allow for AMIDR to return diffusivity results with a higher degree of confidence than Galvanostatic Intermittent Titration Technique (GITT) and at a faster rate with higher state of charge (SOC) resolution than Electrochemical Impedance Spectroscopy (EIS). Below are results of three different, commercial, layered lithium transition metal oxides active materials. These active materials showed very similar kinetic behaviour that varied quantitatively with dependence on the fraction of Ni atoms filling sites in the Li layer. AMIDR comes with a user-friendly python program complete with a user interface that is intended to assist other researchers in measuring active material diffusivity with the same degree of accuracy in a controlled, repeatable manner. This program, along with instruction on its use, the results of this study from raw data to the final key kinetic metrics, and a video summary of AMIDR design are available for download at https://github.com/MitchBall/AMIDR.

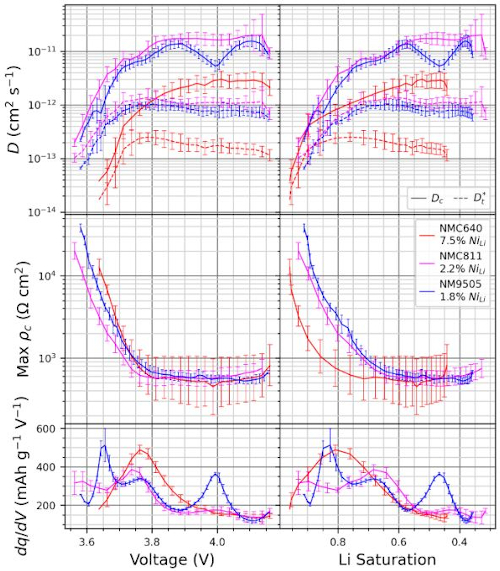

Figure 1

Comparison of commercial layered oxide materials at 30 °C. NMC811 and NM9505 show similar kinetics with similar Ni in Li layer, NiLi, measured with XRD. NMC640 has additional NiLi and worse kinetics.

References

M. Ball, M. Cormier, E. Zsoldos, I. Haman, S. Yu, N. Zhang, N. Phattharasupakun, M. B. Johnson, M. Metzger, C. Yang, and J. R. Dahn, AMIDR: A Complete Pulse Method for Measuring Cathode Solid-State Diffusivity, J.Electrochem. Soc. (in review)

Equipment automation, data analysis and software modeling

The equipment we use is often designed and built in-house as commercial options are either not available, or do not meet the performance levels we require. We produce custom software to control this equipment (typically programmed in VB.NET®) for reliable 24/7 unattended operation.

In addition, many of the group’s research projects generate large amounts of data, We have therefore developed a range of software options for automated data processing, data analysis and graph and presentation generation. Many tools have also been written to model a range of complex processes, such as, for example, dQ/dV or cell impedance changes in lithium-ion cells during charge and discharge.

Figure 2

Images from control and graphical real-time data collection software for 64-channel pseudo-potentiostat test station